Electrolysers

Innovative Electrolysers for Sustainable Solutions

Electrolysers are revolutionising energy systems by enabling clean and efficient hydrogen production. At GreenH, we lead the way in sustainable solutions, offering advanced PEM electrolyser solutions. GreenH will soon offer AEM, SOEC and alkaline electrolyser technologies to support industries transitioning to greener energy.

Innovative Electrolysers for Sustainable Solutions

Electrolysers are revolutionising energy systems by enabling clean and efficient hydrogen production. At GreenH, we lead the way in sustainable solutions, offering advanced PEM electrolyser solutions. GreenH will soon offer AEM, SOEC and alkaline electrolyser technologies to support industries transitioning to greener energy.

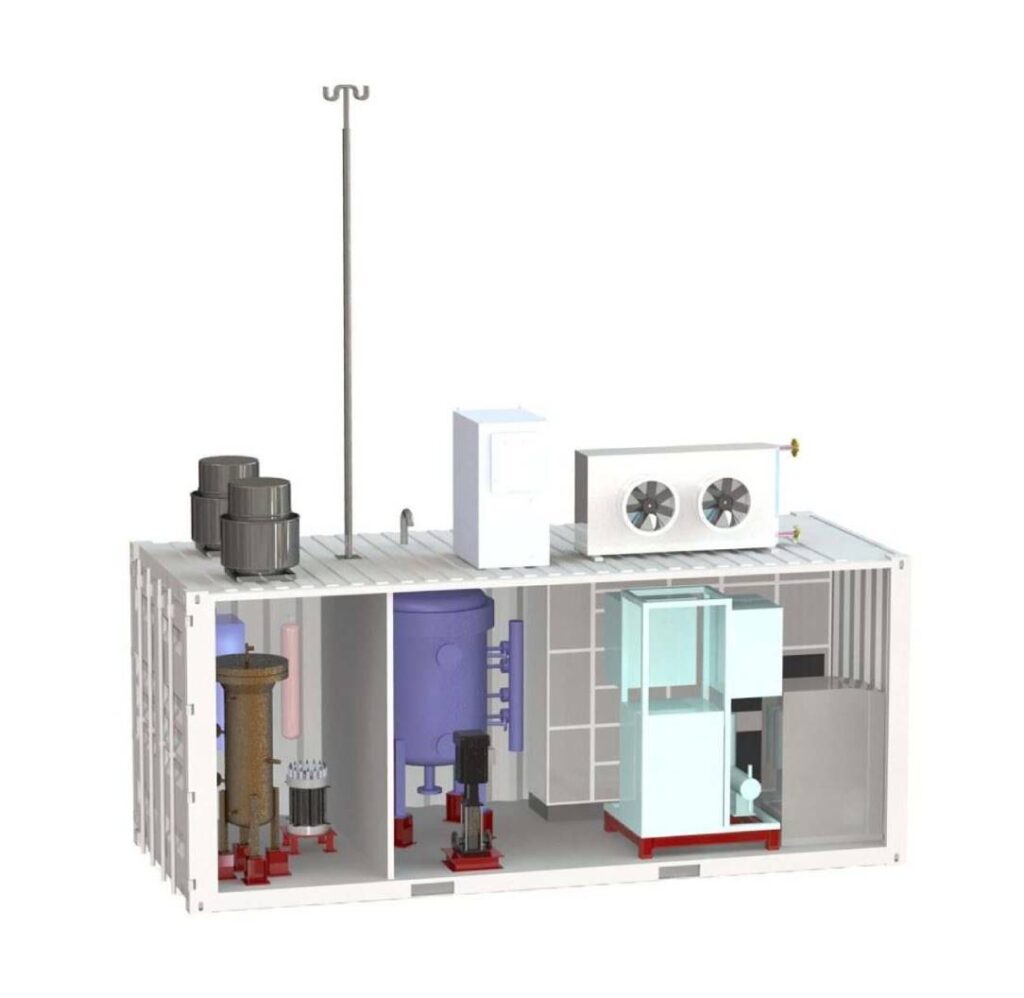

Medium Scale Electrolyser

GreenH’s medium scale of electrolysers are able to supply hydrogen from 10.05 to 63.3 Nm3/h.

These systems are integrated in a container.

GreenH’s electrolysers are certified and developed according to European or American (depending on customer geography) codes and standards.

GreenH supplies electrolysers with CE marking and, if necessary, ETL stamp (priced separately), as well as required safety studies (HAZOP by default).

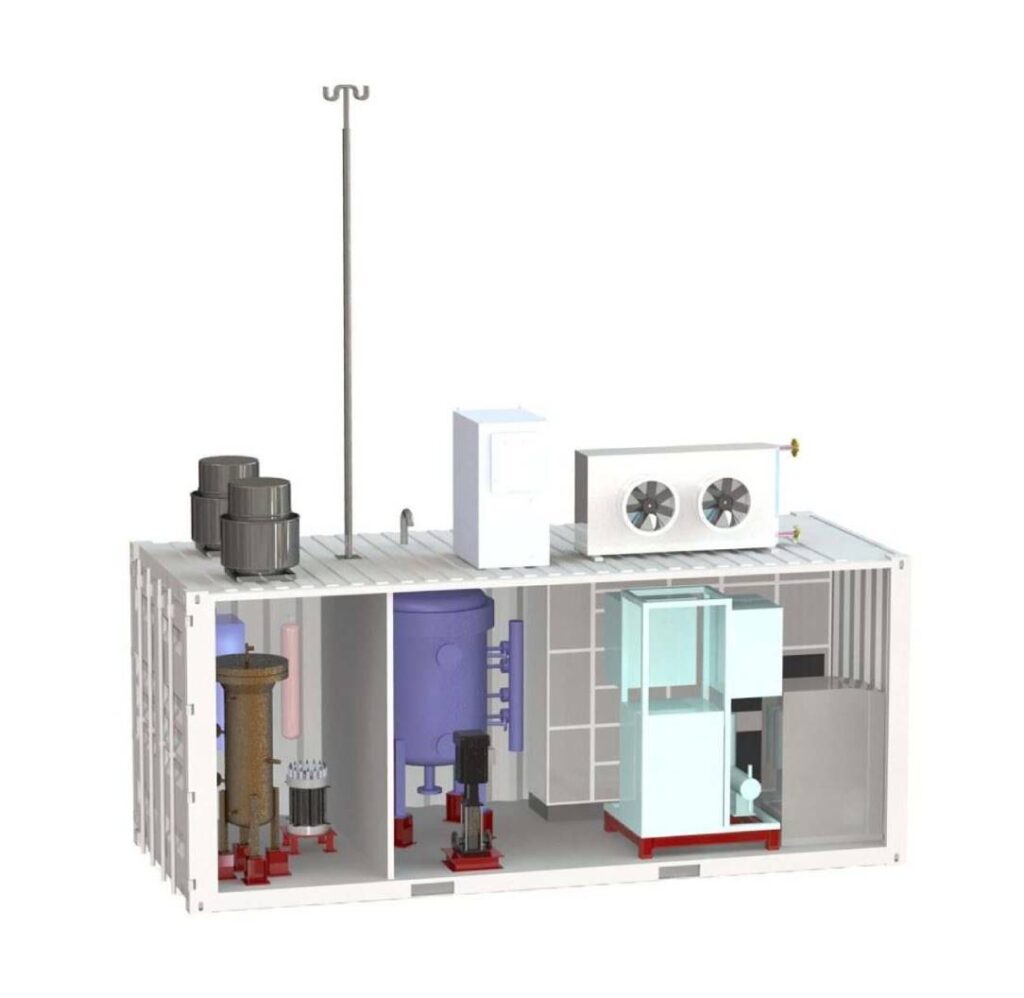

Large Scale Electrolyser

GreenH’s largest-size of electrolysers are able to supply hydrogen from 100 to 600 Nm3/h.

These systems are integrated into a 40ft containers.

GreenH’s electrolysers are certified and developed according to European or American (depending on customer geography) codes and standards.

GreenH supplies electrolysers with CE marking and, if necessary, ETL stamp (priced separately), as well as required safety studies (HAZOP by default).

Importance of PEM Technology and its Role in Green Hydrogen Production

PEM (Proton Exchange Membrane) technology plays a crucial role in the production of green hydrogen. It separates hydrogen and oxygen during the electrolysis process using a membrane, allowing for efficient and clean hydrogen production. PEM electrolysis is particularly valuable because it operates efficiently at lower temperatures and supports the transition to renewable energy by generating hydrogen with minimal environmental impact. This makes PEM technology a key player in the drive for cleaner energy. As PEM electrolyser manufacturers for green hydrogen continue to innovate, the efficiency and sustainability of these systems are poised to improve even further.

Applications of Hydrogen Electrolysers Across Industries

- Renewable Energy Storage: Electrolysers store excess renewable energy—such as from solar or wind—as hydrogen, which can later be used or converted back into electricity. This helps stabilise the energy grid by providing a reliable source of energy during times when renewable generation is low.

- Hydrogen Fuel for Transportation: Electrolysers provide the hydrogen needed for fuel cells that power vehicles, offering a cleaner alternative to traditional fossil fuels in the transportation sector. This is an important step toward reducing the carbon footprint of the automotive industry.

- Industrial Hydrogen Supply: Industries like refining, chemicals, and steel manufacturing need large amounts of hydrogen. Electrolysers supply this hydrogen, enabling cleaner industrial processes. Hydrogen electrolysers are essential for helping these industries reduce their environmental impact while maintaining high levels of efficiency.

- Power-to-Gas: Electrolysers convert renewable electricity into hydrogen, which can be stored and injected into gas grids, supporting the transition from fossil fuels to renewable energy. This process allows energy to be stored in a form that is compatible with existing infrastructure.

Benefits of Choosing GreenH Hydrogen Electrolyser

- Leading Innovation in Green Hydrogen: GreenH electrolysers are at the cutting edge of hydrogen Electrolyser manufacturers worldwide, ensuring high efficiency and sustainability in hydrogen production. Their design sets a benchmark in the industry.

- Reduced Operational Costs with Efficient PEM Technology: Thanks to the efficient PEM technology, GreenH electrolysers help minimise energy use and operating costs, making them a cost-effective solution for various applications. This is crucial for businesses looking to reduce operational expenses while maintaining a clean energy output.

- Versatility for Different Applications: GreenH electrolysers are designed to meet the needs of various sectors, from industrial production to research and commercial applications. Their scalability makes them suitable for diverse operational environments.

- Reliable After-Sales Service: GreenH provides excellent customer support, including maintenance services and troubleshooting, to ensure that electrolysers operate at peak efficiency. This ongoing support helps to maximise the lifespan of the equipment and maintain consistent hydrogen production.

Frequently Asked Questions (FAQs)

An Electrolyser is a device that uses electricity to split water (H₂O) into hydrogen (H₂) and oxygen (O₂) through a process called electrolysis. This allows for the production of hydrogen gas, which can be used in various energy applications.

PEM electrolysers are a type of Electrolyser that uses Proton Exchange Membrane (PEM) technology to produce hydrogen. This technology is known for its efficiency, sustainability, and ability to operate at lower temperatures compared to other types of Electrolysers.

GreenH electrolysers are suitable for a wide range of industries, including renewable energy storage, transportation (for fuel cells), steel manufacturing, chemicals, refining, and power-to-gas applications. They are adaptable for both industrial-scale and research use.

Green hydrogen is produced using renewable energy sources, such as wind or solar power, making it environmentally friendly and carbon-neutral. In contrast, other forms of hydrogen, such as grey hydrogen, are produced from fossil fuels, emitting carbon dioxide in the process.

PEM electrolysers are more efficient, operate at lower temperatures, and require less maintenance than other Electrolyser technologies. They also produce high-purity hydrogen and are better suited for variable renewable energy sources, making them ideal for green hydrogen production.

GreenH electrolysers are designed to meet a variety of production needs, from small-scale applications to large industrial projects. The production capacity can be customised depending on the application and required hydrogen output. Check here for more details.

Yes, GreenH electrolysers can be tailored to meet specific industrial requirements, including varying production scales, hydrogen purity levels, and integration into existing systems.

The cost of a GreenH Electrolyser depends on factors like size, capacity, and specific requirements. For a detailed quote, it is recommended to contact GreenH for a tailored assessment based on your needs.

Yes, GreenH electrolysers are suitable for off-grid applications. Their flexibility and integration with renewable energy sources make them ideal for decentralised hydrogen production, even in remote or off-grid locations.

Alkaline electrolysers are more cost-effective and best suited for large-scale hydrogen production, while PEM electrolysers offer higher efficiency and are ideal for smaller, decentralised systems.

Small-scale electrolysers are compact systems that can be used for localised hydrogen production, ideal for commercial, residential, or research applications.

Several leading Electrolyser manufacturers in India focus on green hydrogen production, providing both alkaline and PEM Electrolyser solutions tailored to various industry needs.

GreenH offers top-notch Electrolyser solutions with after-sales service and custom support, ensuring seamless integration into your green hydrogen initiatives.

GreenH electrolysers combine advanced PEM technology, scalability, and exceptional reliability, ensuring sustainable hydrogen production for a wide range of applications.

Electrolysers Portfolio

GreenH is driving India’s transition to green hydrogen. Whether you’re an industry leader, investor, or policymaker, we invite you to be part of this sustainable energy future.